Industry / Logistics

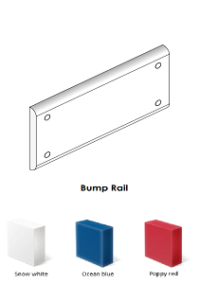

Bump rails and skirting for wall impact protections

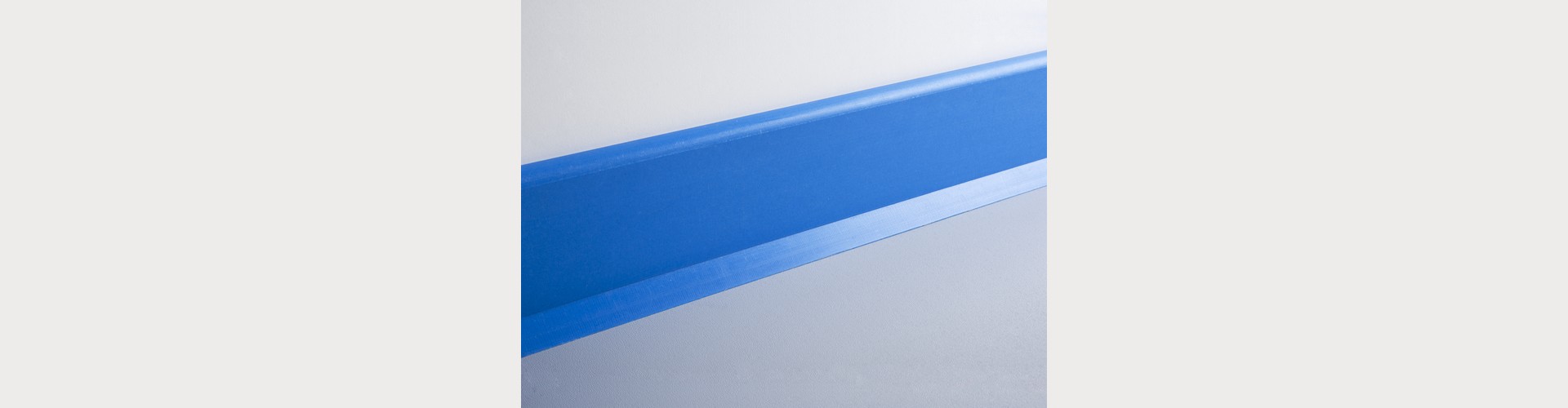

SPENLE wall bump rails and skirting protect infrastructure and fixtures against repeated knocks from pallet trucks or forklift trucks.

Bump rails and skirting for wall impact protection!

Made of solid high density polyethylene, these bump rails and skirting provide real impact protection and are unbreakable! They are totally water-resistant, corrosion-free and unaffected by cleaning products.

ADVANTAGES of wall impact protection systems

- Excellent resistance to knocks from forklift trucks,

- Resistant to water and detergent

- Easy to install

Impact resistant

Washable

Forklifts

Logistics

Industry

Recyclable

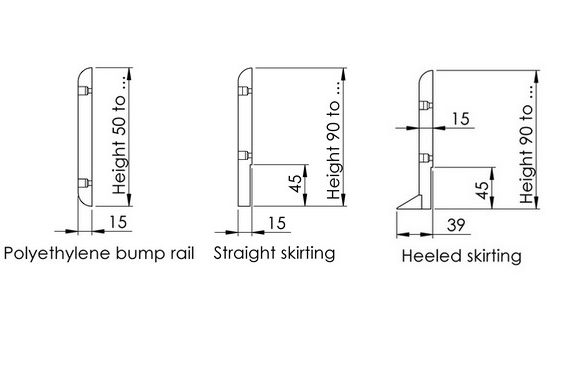

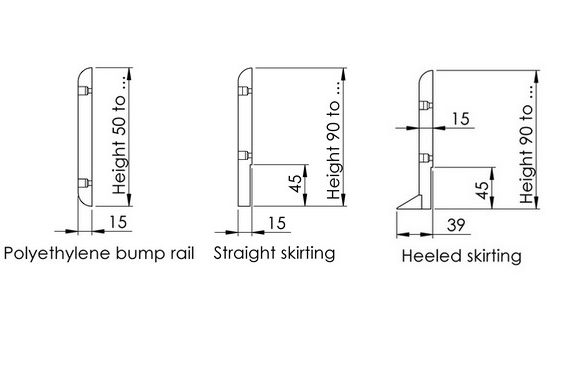

Technical specifications of wall impact protection systems

Polyethylene wall bump rails and skirting

- Made of solid high density polyethylene, they are extremely resistant to knocks and moisture-insensitive,

- The bump rails and skirting are manufactured with rounded edges to limit the depositing of dirt and facilitate washing,

- They are supplied ready to fit (with holes already drilled and flush screw caps for a perfect finish.

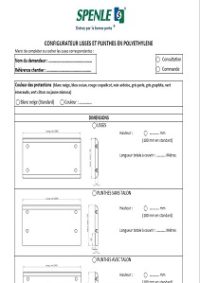

They are available in lengths of 2 metres 15 mm thick as standard, but can also be manufactured to your measurements (width, height, thickness) on request.

The different models of wall impact protectors

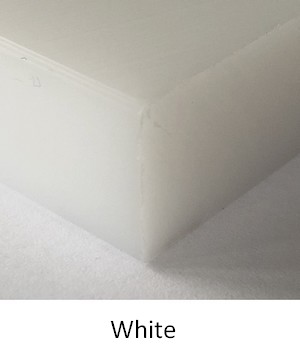

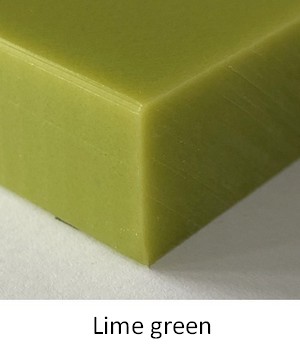

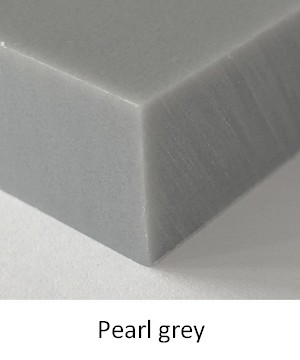

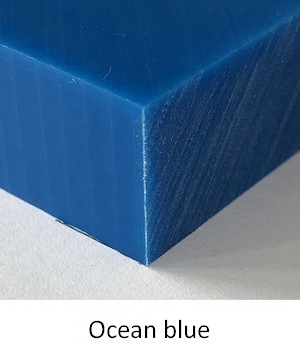

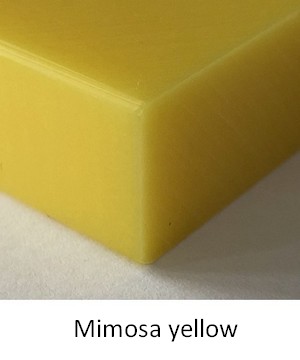

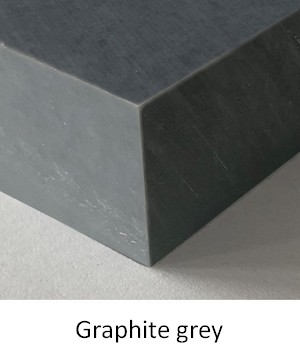

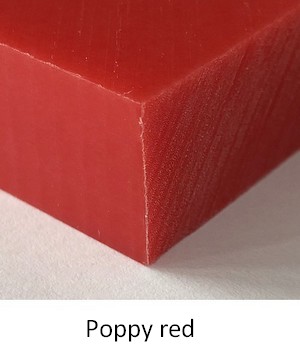

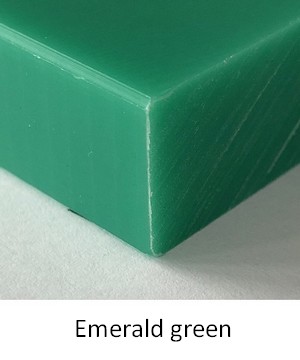

Colours

Variants and options

- Thicker rails or skirting (20 to 40 mm),

- Supplied with stainless steel fastening screws,

- Internal and external corners,

- Bump rails and skirting with seals – partition and/or floor.

More detailed documentation including drawings, BIM files, etc. can be downloaded here.

Examples of uses of polyethylene wall impact protection systems:

- Bump rails protecting partitions in distribution warehouses,

- Bump rails protecting walls on unloading docks.